In the vast world of machinery manufacturing, there is a complicated process that takes center stage. The tolerancing tango is an intricate and rhythmic art form that involves achieving the delicate balance between precision and practicality, a choreographed movement that separates excellence from mediocrity.

From towering industrial behemoths to the intricate mechanisms of miniature devices, precision is the soul that breathes life into these machines. In this blog, we will journey into the realm of tolerancing - the key to unlocking the gates of precision in machinery manufacturing.

Step 1: The Prelude - Understanding Tolerancing Basics

To commence our tango, we must first understand the fundamentals. Tolerancing is the art of specifying permissible limits of variation in a part's dimension, form, and orientation. It acts as a language that communicates the exact requirements to machinists, ensuring that each component fits together seamlessly like pieces of a grand puzzle.

Why are these fittings so important? Having the required precision when manufacturing critical components involved in complex systems can mean life or death - metaphorically or literally. For example, in the tragic loss of the space shuttle Challenger, a gap believed to be 0.050" or less in diameter between two O-Rings and the booster joints resulted in disaster. In mere moments, more than two years of spaceflight and seven lives were lost. While this disaster was caused by the thermodynamic properties of the O-Rings, rather than poor tolerancing, a small difference in dimension can make all the difference.

Step 2: The Rhythm - Balancing Precision and Practicality

Like a graceful dance partner, precision and practicality must move in sync. While tighter tolerances result in superior accuracy, they can balloon production costs and lead to longer manufacturing times. The challenge lies in striking the right balance - achieving the highest level of precision possible without compromising functionality or breaking the budget.

Budget is often why different components often have their unique tolerancing requirements. To keep costs low, manufacturers have more lenient tolerances in areas where the exact dimensions are not critical to the integrity or fitting of the parts. Conversely, in areas where precision is essential, manufacturers require the appropriate tolerance for manufacturing.

Step 3: The Dance of Materials - The Role of Material Selection in Tolerancing

Just as dancers require the right shoes for a flawless performance, materials play a pivotal role in the tolerancing tango. Engineers must meticulously consider the properties of various materials, their thermal expansion rates, and other characteristics that influence dimensional stability. The choice of material can make or break the precision dance.

Several different material properties can lead to a change of preference for the manufacturer. Elastic modulus, thermal expansion, and material hardness are common elements considered when machining.

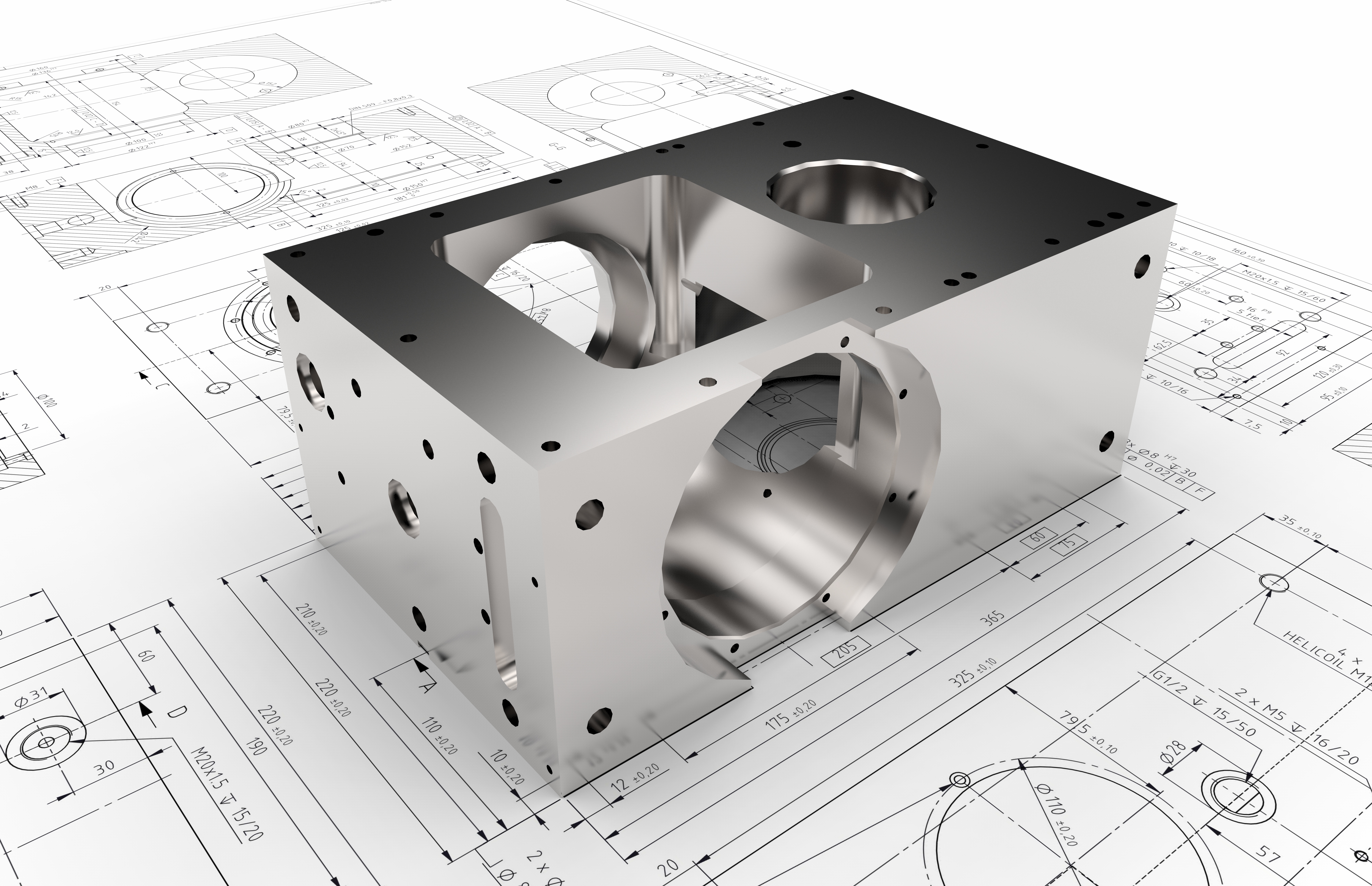

Step 4: The Choreography - CAD and CAM in Tolerancing

In this digital age, technology waltzes hand-in-hand with tolerancing. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems guide engineers, providing virtual rehearsals before the actual performance on the factory floor. These sophisticated tools ensure that every movement is meticulously planned and flawlessly executed.

Step 5: The Grand Finale - Quality Control and Inspection

No performance is complete without applause, and for tolerancing, this comes in the form of stringent quality control and inspection. Advanced metrology techniques such as Coordinate Measuring Machines (CMMs) and Optical Inspection systems take the stage to verify the precision achieved, guaranteeing that each step of the dance was executed flawlessly.

Step 6: The Evolution - Advancements in Tolerancing Technology

As with any art form, the tolerancing tango evolves. Advancements in manufacturing processes, the rise of Industry 4.0, and the integration of Artificial Intelligence (AI) usher in a new era of precision. With each passing day, engineers find new ways to push the boundaries of what is possible, crafting machines of incredible accuracy and efficiency.

The Greatest Dance in Machining

In conclusion, the tolerancing tango is a mesmerizing dance of precision and artistry that underpins the world of machinery manufacturing. It requires a delicate understanding of tolerances, material science, and cutting-edge technology to achieve perfection. With each rhythmic movement, engineers bring to life a symphony of machines that drive progress and innovation across industries. So, the next time you marvel at a finely crafted piece of machinery, remember the hidden elegance of the tolerancing tango, where every step is an ode to the pursuit of precision.