Today, 3D printing is a valuable tool for almost every industry from car manufacturing to medical devices to food production. Layer by layer, this form of prototyping is evolving into one of the most revolutionary production techniques around. How did 3D printing get its start?

The Early Days of 3D

It might seem like the concept of 3D printers is a new one, but 3D originated in the 1800s. In 1859, a sculptor from France demonstrated a way to get a 3D look using photographs.

Prototyping technology first surfaced in the 1980s. Hideo Kodama of the Nagoya Municipal Industrial Research Institute visualized using two additive methods to create three-dimensional plastic models with thermoset polymer.

The Advent of Stereolithography

Just a few years after Dr. Kodama’s attempt to make plastic models, three engineers from France officially patented stereolithography — the art of creating 3D prototypes or models using layering and a photochemical process.

Around the same time, Chuck Hull filed a second similar patent. He had a technique for generating three-dimensional objects using photopolymers cured by ultraviolet light lasers. Hull stated he was able to create 3D objects by building a cross-sectional pattern layer by layer.

Betsy

In the late 1980s, Carl Deckard built what today is known as the first 3D printer. His machine, called Betsy, would turn loose powder into solid objects. The printer’s laser was able to bind the powder together, solidifying it into something tangible.

Fused Deposition Modeling

In 1988, inventor S. Scott Crump and his wife Lisa expanded on the stereolithography concept to create fused deposition modeling — the process utilized by today’s 3D printer. Sometimes called plastic jet printing, this process uses the additive principle to create objects in 3D. Fused deposition modeling involves melting a polymer and then using it to create an object layer by layer.

The technology continued to evolve to make creating objects more accessible and more affordable. In 2004, mechanical engineer and lecturer Adrian Bowyer founded the open-source RepRap project with a goal of creating a 3D printer able to make its own components.

In 2008, the first 3D consumer service company, called Shapeways, opened in the Netherlands. It provides 3D printing on demand; consumers submit files to Shapeways, which creates and ships the object directly to the person or company that ordered it.

In 2013, Samantha Snabes and her NASA colleague built a large-format, cost-effective 3D printer and launched their company, 3D, to market them; 3D looks to put 3D printers in households and businesses.

3D Printers in the Real World

Today, experts believe 3D printing can improve lives in developing countries and help eliminate plastic waste. The company 3D already makes use of pellets made from old plastic objects to create new objects.

Food entrepreneurs are also developing ways to “print” vegan meat products from plant resources. Researchers are exploring 3D printer alternatives that allow surgeons to customize tools while in the operating room, and they're experimenting with making replacement organs using the patient’s tissue to eliminate the need for cadaveric and human organ donors.

What started as a desire to render plastic models easily has grown into the thriving 3D printing industry.

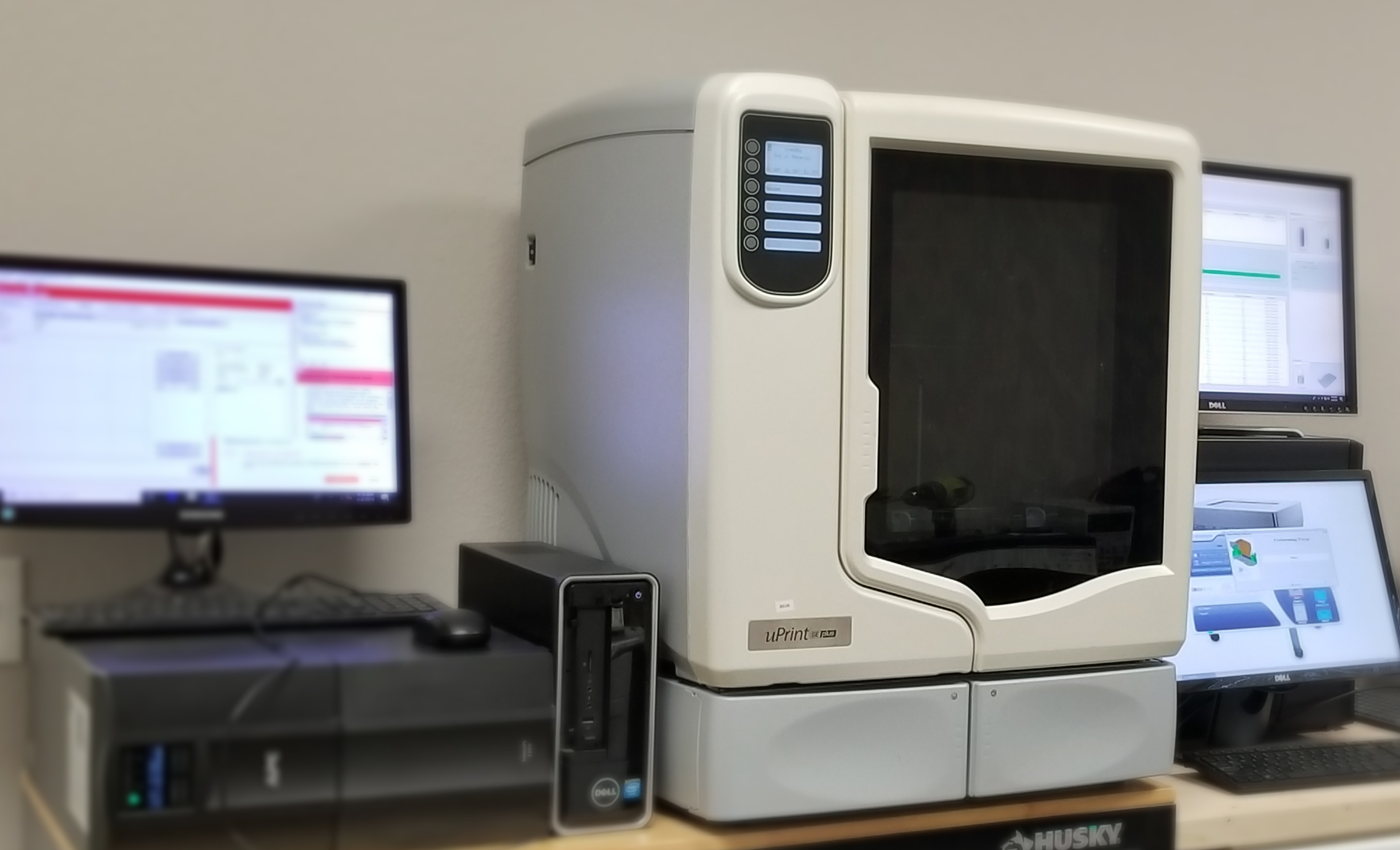

We love our 3D printers and we use them almost daily to create prototypes of products we are working on.